How the Mill Works

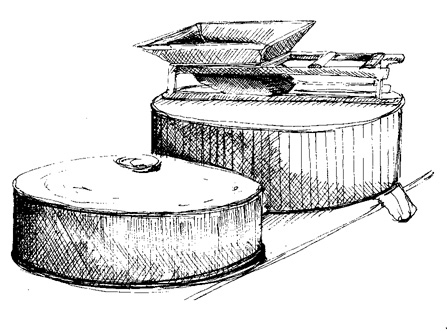

It starts with the grain… Of course, grist mills grind a variety of grains, such as wheat, rye and corn. But in Rhode Island, particularly at Gray’s Grist Mill, native grown corn, particularly Narragansett White Flint Corn, is the most common “grist for the mill.” The corn is husked, then dried for 6 to 8 months. It is then shelled and bagged for milling. Into the Hopper… The dried, shelled corn is then poured out of the bag, and into the hopper. The hopper, of course, is the receptacle above the grinding stone. A vertical rod, called the “damsel,” is then used to shake the kernels downward, through the “shoe” and into the millstone. The hopper releases an average of three bushels of corn an hour for grinding.

About the Millstones…

The two millstones at Gray’s Mill are 15 inches thick, and weigh 1 1/2 tons each. An enormous tonnage, considering that one was imported from France. The 4′ French Bhurr Stone was used for wheat and rye, and the 56″ Granite Stone is used for corn. The grinding surface of these “runner” stones, or top stones, is concave and carved in spoke patterns. The runner stone sits atop another “bed stone” or “nether stone,” which is also carved. As the top stone rotates, the grain first gets cracked in the middle of the two stones, then is pushed to the outside by the spoke-like pattern. The finest grinding occurs along the perimeter. When the millstones need to be cleaned, sharpened or repaired, the runner stone is lifted with a Stone Crane, using a hand screw jack.

The two millstones at Gray’s Mill are 15 inches thick, and weigh 1 1/2 tons each. An enormous tonnage, considering that one was imported from France. The 4′ French Bhurr Stone was used for wheat and rye, and the 56″ Granite Stone is used for corn. The grinding surface of these “runner” stones, or top stones, is concave and carved in spoke patterns. The runner stone sits atop another “bed stone” or “nether stone,” which is also carved. As the top stone rotates, the grain first gets cracked in the middle of the two stones, then is pushed to the outside by the spoke-like pattern. The finest grinding occurs along the perimeter. When the millstones need to be cleaned, sharpened or repaired, the runner stone is lifted with a Stone Crane, using a hand screw jack.

Turning the Millstones… Traditionally, the millstone rotates by waterpower. At Gray’s Mill, a Sluice Gate was used to start and stop the flow of water from the mill pond across the road. The Sluice Gate was opened by a turning Sluice Wheel, which starts the flow of water, causing the water wheel to turn, thus providing power to grind the grain. Eventually, as water levels in the mill pond became unreliable, drying out during much of the year, water power at Gray’s Mill was supplemented with a 1946 Dodge truck engine from an old Cain’s mayonnaise truck. By 1960, the mill was powered entirely by this engine. Now the mill utilized electric power.

Separating the Chaff… As the ground corn falls from the grain spout, it is filtered through a mesh screen that sifts out the courser pieces of the corn’s bran, or outer layers. On to the Market… Freshly ground sacks of corn are then hauled into the bagging room, where it is weighed on a scale and hand-bagged. Since traditionally milled corn contains none of the preservatives found in store bought grains, it should be kept refrigerated to preserve freshness.